Recommended Products

Recommended Products

Recommended News

Recommended News

Introduction of additives for shale gas fracturing

Introduction to SV-15FW76 high viscosity polymer fracturing technology

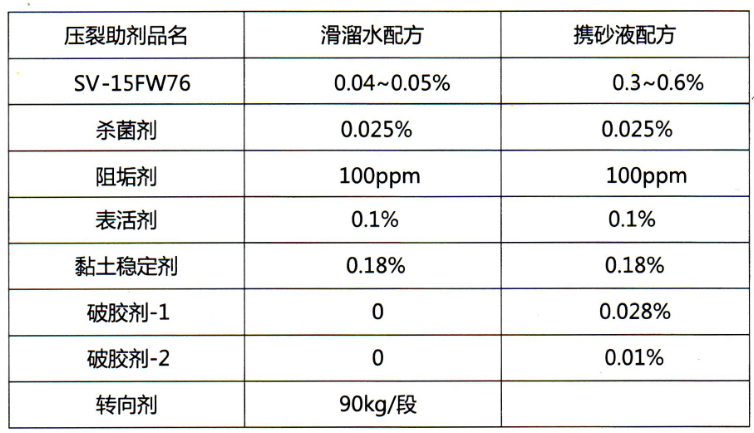

SV-15FW76 is a synthetic polymer that can be used as both slick water drag reducer and linear rubber thickener.

SV-15FW76 is a multifunctional fracturing fluid system designed to be used as a linear gel system. ● This technology provides 10-70cPs viscosity and maintains good sand carrying capacity. ● It is beneficial to reduce the amount of chemicals used on site.

● This product also helps to provide effective cleaning and increase production.

Use as drag reducing agent: the recommended dosage is 0.04% - 0.1%, and the specific concentration depends on the water quality. Use as linear adhesive: salt resistance is up to 7%, containing 1% divalent ion. The specific dosing depends on the system. The recommended dosage is usually 0.2% - 0.8%.

According to different systems and water quality. At 0.4% dosage, 18 and

70 cP viscosity.

SV-15FW76 can obtain the required viscosity at different concentrations. This product has the characteristics of almost instantaneous hydration and can be directly

Add to the mixer. The data in the table shows that SV-15FW76 provides higher viscosity at different shear rates and is stable at various shear rates.

Product features

● Provide consistent fracturing fluid ● Excellent drag reducer at high pump speed ● Effectively provide viscosity and sand carrying performance ● Effective and consistent pressure control between different fracturing sections ● Good compatibility with other fracturing fluid additives ● Reduce operational and environmental complexity and reduce costs

● Non-damage fracturing fluid system, less damage compared with common cross-linking fluid

Product advantages:

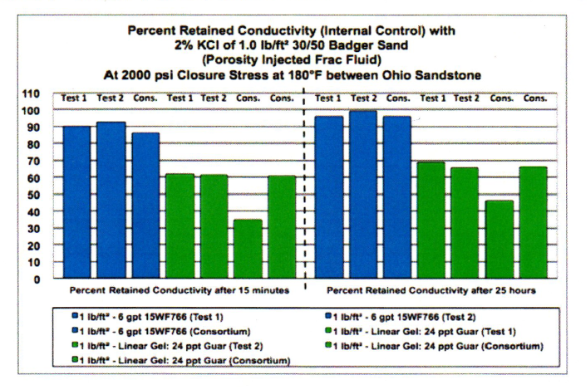

(1) 15FW76 (blue) and guar gum (green) permeability recovery comparison (test results in Stim-Lab laboratory)

Compared with guar gum liquid (green), it has strong sand carrying capacity - providing higher permeability recovery capacity

15FW76 is designed to provide better plastic properties than linear guar gum with the same dosage. This can make 15FW76 more effectively suspend proppant and carry sand deeper and farther into the fracture. Many studies on the use of proppant under the conditions of tap water and room temperature showed that 15FW76 had a slower sedimentation rate than linear guar gum under the same dosage and static conditions. Lower sedimentation rate is conducive to easier re-pumping after unexpected shutdown.

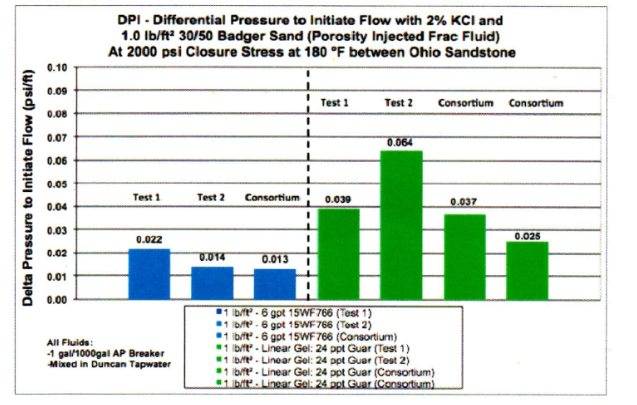

(2) Comparison of initial flow pressure difference between 15FW76 (blue) and guar gum (green) (test results in Stim-Lab laboratory)

Compared with guar gum solution, improved proppant slug cleaning and permeability recovery

Another advantage of 15FW76 compared with guar gum is the cleaning of proppant slug. Melon gum contains about 9% insoluble residue after processing. Oxidative gel breaking also increases the proportion of insoluble substances. 15FW76 contains less or almost zero insoluble matter, and is easy to be broken by oxidizing substances. There is no insoluble material that can easily block the pore throat.

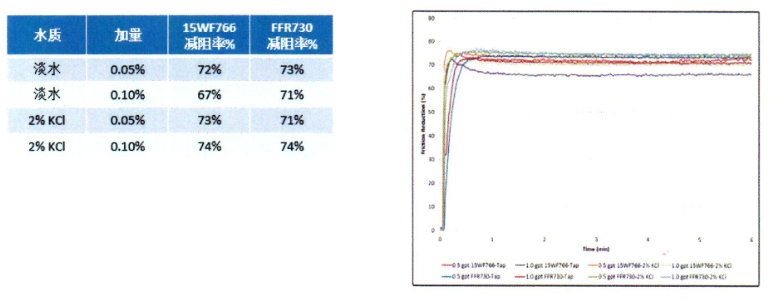

(1) Friction reduction rate test, comparison of friction reduction rate of 15FW76 and FFR730 in tap water and 2% KCl at room temperature

Complete fracturing system

QQline

Telephone

Website