Recommended Products

Recommended Products

Recommended News

Recommended News

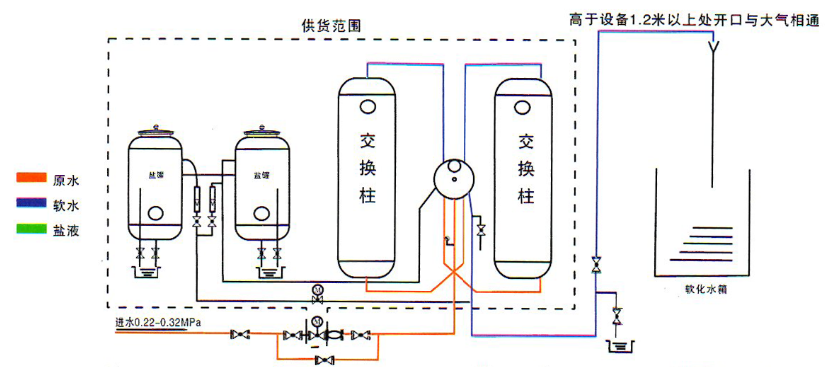

The equipment is composed of two exchange columns, a plane integrated valve, a microcomputer controller and a salt tank or salt tank. Through microcomputer control, the equipment drives the plane valve to realize the liquid phase switching by rotating and aligning, changes the flow and direction of raw water, demineralized water, salt water and waste water in the equipment, automatically completes the auxiliary operation and softening process, and circulates according to the set time. working principle

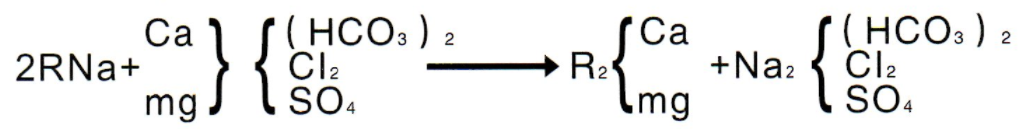

Exchange agent is 001 × 7 Strong acidic styrene cationic resin, NaCl as regenerant, countercurrent regeneration process. The raw water is exchanged by Na+, expressed by the following formula:

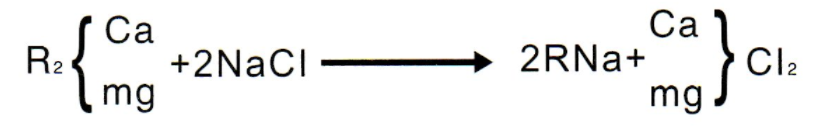

During regeneration, Ca "and Mg" adsorbed by Na 'ion resin are exchanged by Na to restore the exchange capacity of the resin.

After the water is exchanged with Na ion exchange resin, its residual hardness meets the requirements of low-pressure boiler feed water.

Workflow:

1 # exchange column water production → water production → water production → water production → loose bed → regeneration → replacement → cleaning Circulating 2 # exchange column loose bed → regeneration → replacement → cleaning → water production → water production → water production → water production... circulating

001 × 7 Strong acidic styrene cationic resin is installed in two exchange columns to float and soften the raw water. Two exchange columns work alternately to produce water continuously, one exchange column produces water, and the other exchange column performs bed loosening, regeneration, replacement and cleaning. The regenerant (industrial salt) solution stored in the salt tank or salt tank enters the multi-functional plane valve after being diluted by the rotameter, and is regenerated by the countercurrent regeneration process. The waste liquid is discharged through the waste pipe of the plane valve, and the replacement is the further regeneration of the resin, making full use of the salt liquid. Finally, clean the resin thoroughly with large soft water.

Work flow chart:

QQline

Telephone

Website